Another advantage you’ll appreciate with Fort Recovery Industries is our unique ability to provide cost-competitive secondary processes of first-rate quality. As a result, you receive the finished components you require in one efficient step – components that give you a superior product.

Electroplating

- Polished Chrome

- Satin Nickel

- Satin Chrome

- Brushed Copper

- Simulated Stainless Steel (China JV)

- Polished Brass PVD (China JV)

- Many others – tell us what you would like to match!

Other Plating/Coating

- Zinc Barrel Plate

- Zinc/Chromate Barrel Plate

- Trivalent Chrome Conversion

- E-coat

Powder Coating

- Chain on edge automated powder coat systems

- Batch powder coat system

- Rack system (China JV)

Machining

- CNC machining (2 & 3 Axis)

- Drilling, tapping, turning, reaming, and milling

- Broaching

- Automated tapping

- Indexing table tapping

- Numerous sizes of equipment from single to multiple stations

- Custom machining work centers

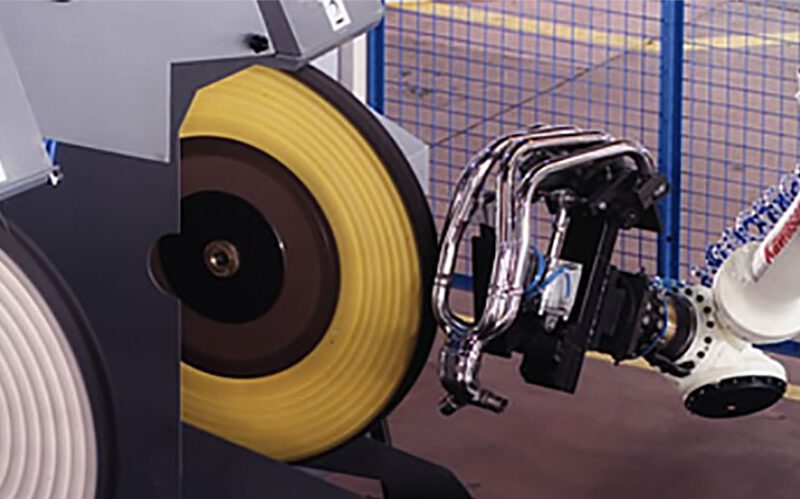

Robotic Sanding & Polishing

Finishing

- Vibratory finishing bowls (bowl and inline)

- Bulk water tumbling

- Bulk tumbling drum

- Shot blast

- Barrel & conveyor wash and dry systems

Buffing

- Semi-automatic buffing machines

- Hand buffing and sanding equipment

Pad Printing

Decorative Painting

Assembly

- Light assembly of components both produced and purchased

- Custom assembly stations

- Stamping

We’re one of the few fully integrated zinc and aluminum die casters that offers expertise from design through finishing and assembly.